WHAT IS A CONCRETE SURFACE PROFILE?

Concrete Surface Preparation is the Most Important Part of any Quality Floor

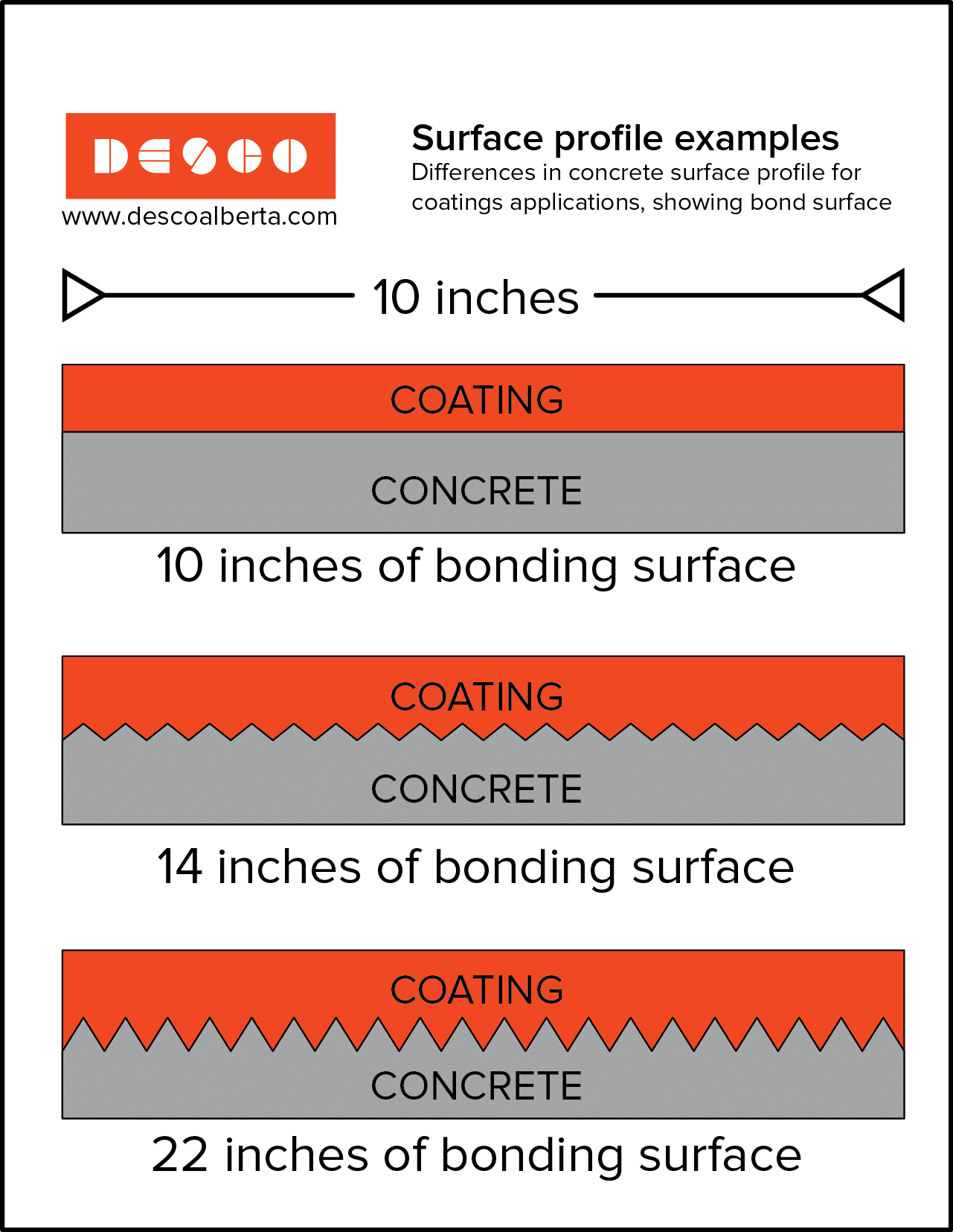

The most important step in creating a quality floor is the preparation. You need to properly prepare the floor with the proper concrete surface profile for the proper bonding of any coating, mortar, or overlay. But what is a concrete surface profile? A concrete surface profile, known as a CSP, is a standardized measure for the ‘roughness’ of a surface that is defined by the International Concrete Repair Institute (ICRI). A very rough surface will have a high CSP number, such as CSP 10. A very smooth surface with almost no preparation at all will be a CSP 1.

The concrete must be properly cleaned and degreased before any concrete surface profile is installed. Grease, oil, sealers, and other contaminants will effect the bond of the intended finish. Contaminants will be driven into the concrete and cause future issues if they’re not removed before profiling the concrete. Solvents should be avoided as they can drive contaminants into the concrete.

The proper CSP will be decided by four factors:

1. THE TYPE OF COATING/OVERLAY BEING INSTALLED

This will be specified by the product manufacturer and determined by the thickness of the application. Thicker applications, such as overlays, will have rougher surfaces (CSP 6 and up). Thin film coatings usually do not require an overly aggressive floor texture, such as a CSP 3-4.

2. PROJECT CONDITIONS

Can the project accommodate our big grinders and scarifiers that weigh hundreds of pounds? Or will we have to prepare the surface with hand-held grinders? Even with a wide range of equipment in different sizes, not every option will be available for every job.

3. OWNER REQUIREMENTS

The owner may restrict the amount of noise, dust, and vibrations that can occur.

4. THE CONDITION OF THE SUBSTRATE

If the substrate is in good condition, you will not have to remove as much damaged material. If the substrate is damaged, a more aggressive CSP may be required.

Different CSP are achieved by using different machines and methods of concrete profiling. You can profile a surface through abrasion, expansive pressure, pulverization, and impact. Again, not every method is perfect for every job. The floor should not be damaged when preparing the floor, otherwise, there will be more repairs required.

ABRASION

Abrasion will cause the progressive disintegration of the concrete surface through erosion. This will result in a flat and fairly uniform surface. Abrasion results in almost no surface damage and a very low CSP number(CSP 1-2). Abrasion is commonly done by diamond grinding. Diamond grinding will leave a CSP 1 or 2. Diamond grinding cannot achieve a CSP 3 no matter what type of tooling is used.

EXPANSIVE PRESSURE

Differences in heat will cause expansive pressure. The surface is heated very quickly to a high temperature, causing the top to scale off. As a result, the surface quite rough (CSP 6-9). This is usually done with flame blasting, water jetting, and steam blasting.

PULVERIZATION

Material is removed through the repeated collision of small particles traveling at a high rate of speed. The small size of the particles limits the damage caused to the surface. This method produces a highly profiled surface (CSP 2-8) with very little surface damage. Pulverization (abrasive blasting) is commonly done by sandblasting, vaporblasting, and shotblasting. Sandblasting and vaporblasting are open processes; the abrasive that is expelled in the process is not recovered and spreads into the adjacent atmosphere. Shotblasting is a closed system; the metal abrasive shot is recirculated throughout the machine and dust is removed from the particles by a HEPA vacuum system. This limits the spread of silica and provides a clean surface.

Most coating manufacturers require a CSP 3 or greater for their coatings.

IMPACT

The substrate is repeatedly impacted by a hardened point, causing the substrate to crumble. Impacting the surface will fracture the aggregate and cement paste, causing the most surface damage, but providing a very rough profile (CSP 4-9). Impact is done with a bush hammer bit, scarifying, scabbling, milling, and scaling. Surface bruising from impact methods can be removed by abrasive blasting.

WHAT TO LOOK FOR WITH SURFACE PREPARATION

When talking to your contractor, ask them what surface profile they’ll be providing. Ask them which surface profile the manufacturer recommends for the material being installed. If you’re going to be paying for a quality flooring material to be installed, you should make sure that the floor is properly prepared.

Any type of surface preparation installed should be consistently applied over 100% of the floor. A floor that is diamond ground should be 100% the same texture with no visible swirl marks. A floor that is shotblasted should not have missing strips of floor.

All too often we’ll go to a job and see that the contractor who did the work before us did not follow any of these steps and thought the material would just magically stick. Magic isn’t real, but the mess on your floor sure is.

So if you’re unsure of what steps should be taken, call us and we’ll be glad to help you out. Or, download our checklist of questions to ask your contractor.